.png)

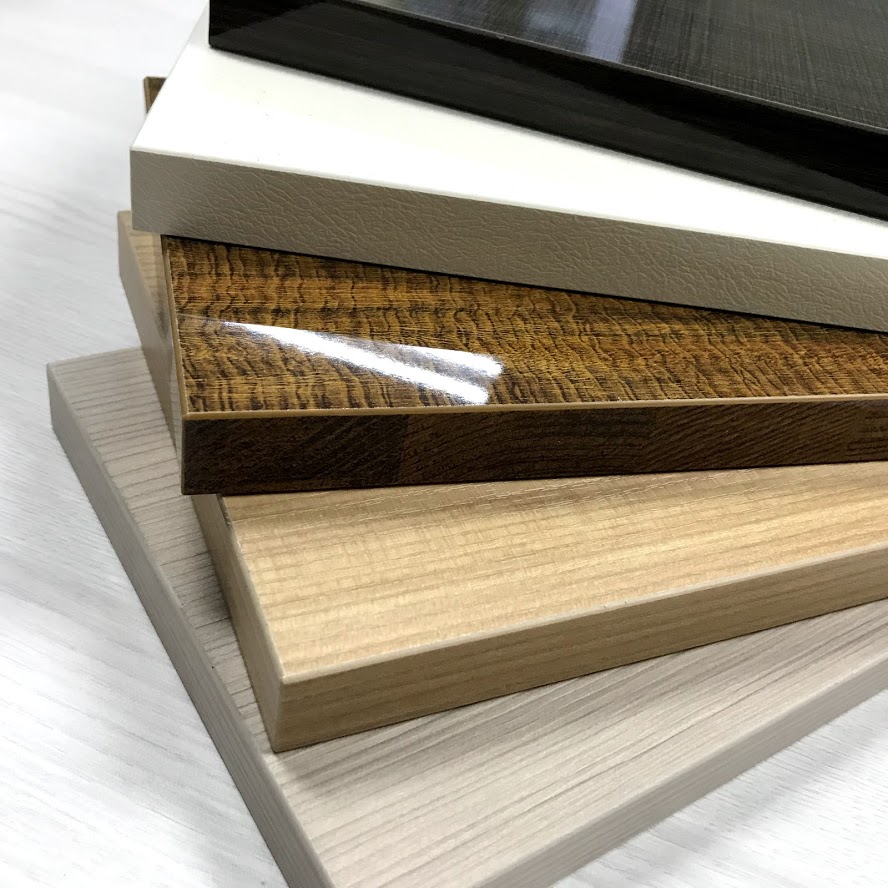

Laminate sheet color range is very diverse.

Laminate is a material used in the furniture industry, also known as HPL (High Pressure Laminate). Laminate sheet is the main component of kraft paper that handles phenolic glue dipping, presses under pressure (about 100 kg / cm2) and high temperature (150 ° C), the surface is decorative paper dipped with melamine glue. Laminate panels are often used to make decorative surfaces instead of natural wood or stone veins in the field of furniture, household furniture such as tables and chairs, cupboards, kitchen cabinets, partitions or wooden floors. with a thickness from 0.6mm to 1.2mm, the most commonly used thickness is 0.8mm.

The history of laminating began in 1896, Leo Baekeland - an American chemist who first tested the fabrication of laminates, which was patented around 1913 by Herbert A. Faber and Daniel J O'Connor, the first to develop the Formica brand. These original laminate sheets can only be black or brown (the color of kraft paper, and are mainly used in the electrical industry due to its insulating properties).

By the 1930s, the decorative and patterned surface layer of Laminate panels appeared to have made it a popular choice in the field of furniture, especially in buildings requiring durability and aesthetics. high. A prime example of this period, many cafes, trains and ships like RMS Queen Mary used Laminate panels as decorative surfaces.

The real time of the Laminate industry's boom was after World War II ended. Especially in the 1950s because at this time, Laminate panels are recognized for their high aesthetics, practical applicability, ease of cleaning and durability. Also in these years, the material market witnessed the development of a unique anti-flammable function of Laminate panels.

In 1968, the Dunhams Washrooms was founded, which manufactures sanitary panels, ceiling tiles, office screens and lavabo cabinets. This is one of the first manufacturers to use Laminate panels as a decorative surface layer for these products. Now more than 50 years, this company is still growing very strongly.

Structure of layers of laminate panels

Laminate panels are usually made up of 3 layers: the surface layer, decorative paper layer and many kraft papers that are simultaneously pressed under the temperature of 150 ° C and 100kg / cm2 pressure.

Surface layer: is the layer that creates surface effects and protects the laminate panels when touching hands, usually on the market with glossy, grainy, smooth or synchronized effects with wood grain.

Decorative paper: Decorative paper and colors embedded in MUF glue (melamine urea formaldehyde) with high scratch and abrasion resistance. The pattern and color of the laminate are determined by this decorative paper.

Kraft paper layer: Including many layers of kraft paper treated with phenol adhesive. The thickness of Laminate depends on this layer, if you want to increase the thickness, increase the number of kraft paper. Kraft paper is a type of high-strength paper, usually brown, creating a brown or black core typical of kraft paper.

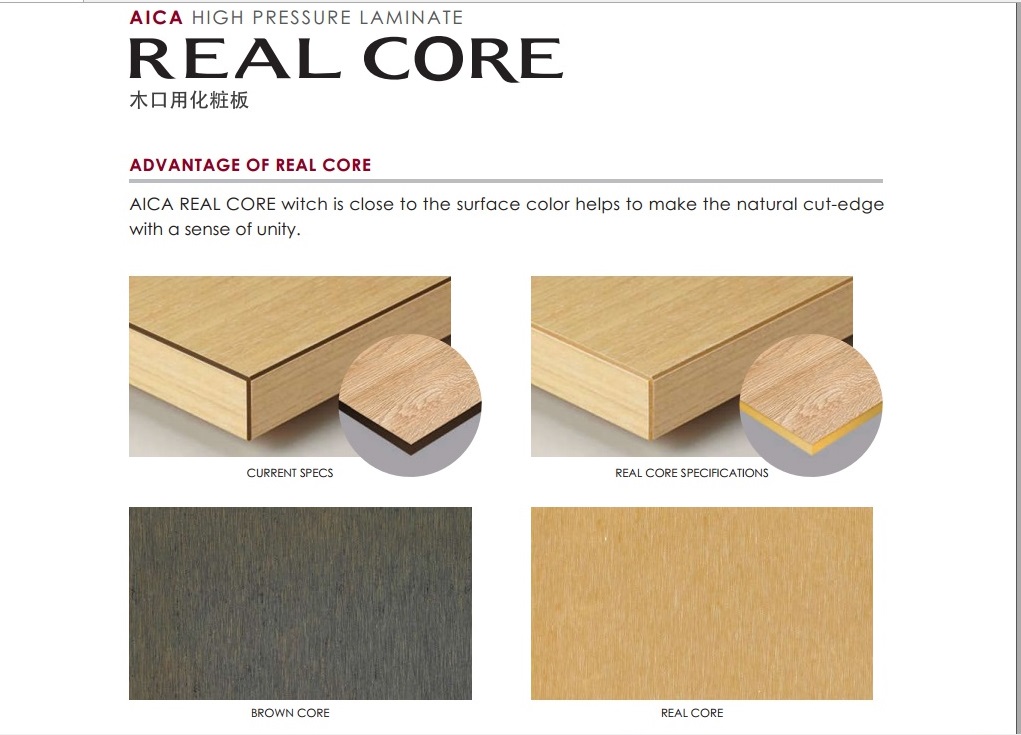

Edge laminate panels when using Laminate and copper-core Laminate panels.

In general, Laminate panels are composed of 3 layers as in the composition of the surface layer, decorative paper layer, kraft paper layer. However, to suit the needs and aesthetics of the market, currently, Laminate panels can be divided into 2 types as follows:

Kraft paper used to make laminate sheets is usually brown, after dipping the glue, it becomes dark brown or black. Therefore, the back of the laminate is usually brown and black. The problem is that when cutting edge V or L, the back will be exposed when the Laminate sheet has a bright color like white, cream. Therefore, the leading manufacturers of Laminate, typically AICA Japan, have researched and launched a product line that meets this requirement, namely single-color plain and single-core copper Laminate panels. . Particularly, patterned white copper core and wood grain gold core are only available in Vietnam market.

Copper core laminate panels are laminate panels with similar back and surface parts. Currently, AICA has 2 types: Laminate with yellow core and white copper Laminate. For white-core copper laminate using white kraft paper, the back part will be white, consistent with the surface with bright tones such as white, cream, light gray. For copper-core Laminate panels using yellow kraft paper, the back side will be yellow, consistent with the part with bright wood tones.

The outstanding advantage of copper-core laminate panels is its high aesthetics. Instead of revealing the black border like regular laminate panels, when using a copper core laminate, the product will be uniform in color.

Used for difficult positions such as table top, chair back, bedside, cabinet side for families with children to avoid impact, or furniture items that require high aesthetic to replace edge banding. Laminate bend - post forming without surface (including glossy surface) is a strength of HPL Group as well as Aica Laminate.

Laminate sheet price on the market today

Laminate AICA surface laminate wood sample

Because the current market demand for Laminate is very high, many manufacturers are interested in this lucrative piece. One of the top competitive factors is price. Laminate panels have a variety of prices for consumers to choose from, from cheap to premium, depending on the needs of the buyer.

Low-cost laminate panels are often discounted on kraft paper, glue, or thickness reduction. Therefore, when using cheap products, the durability will not be high, resistant to moisture, abrasion, scratch, poor fading. However, with the advantage of cheap prices, there are still many consumers who choose moderate laminate panels to install. Most of the origin of cheap Laminate panels comes from China and India, the country of billions of people - the world's factory is really good at processing products at arbitrary prices.

High-grade laminate panels usually come from developed countries such as Europe, Japan, Thailand ... The most famous brand of laminate production in Japan market is AICA Laminate.

In the same field of application with laminate panels, we have a lot of other materials such as acrylic, melamine paper, veneer, etc. However, laminate panels are currently the most popular raw material. Why is that? Because Laminate panels have the following outstanding advantages:

Diversity of designs, colors: Because the layer that decides the color pattern of the laminate is decorative paper, this paper prints based on the design image on the machine. Therefore, Laminate panels have the ability to simulate any pattern, shape of any material such as wood, stone, leather ... with grained, glossy, ...

Tough: Some types of Laminate have the ability to bend and glued with post forming technique, this technique brings high aesthetics to the edge of the table, cupboard, ...

High strength, bearing capacity, abrasion resistance, persistent impact resistance: The surface layer is a transparent melamine adhesive that stays inert under the prescribed temperature and pressure, helping to increase unsurpassed durability. whole Laminate sheet surface.

Highly insulating, heat-resistant: Due to its insulating ability, the first time appeared, the precursor of Laminate sheet was used as an insulating material in the electrical industry. It was not until later that people studied improvement and application of melamine panels in the field of furniture and construction. Besides, the heat resistance of Laminate panels is very good. According to a study, laminate panels can withstand temperatures up to 180 degrees Celsius for up to 20 minutes.

Easy to clean: With surface layer made from inert melamine resin, Laminate sheet is very limited to stick to dirt and easy to clean. AICA has a proprietary technology, the Celcus series, that creates a laminate sheet that is true to the color of natural wood, both anti-glare and fingerprint-proof, based on a special Nano surface coating.

Price is more comfortable than natural materials, suitable for economic conditions of many consumers.

Environmentally friendly: Laminate panels do not use natural wood, so protect the forest environment.

AICA Wonder series laminate panels clad in the hotel lobby wall

Besides natural wood, natural stone, simili ... suitable for the tastes of the older customer segment, the young customers mostly prefer modern materials such as laminate. Laminate panels with patterns updated the trend, highlighting the fresh vitality, dynamic beauty and modernity of the living space. In life, we can apply Laminate panels in areas and items such as:

Use Laminate panels to make home and office tables and chairs: The surface of home tables and chairs, offices often use wood grain Laminate panels. The culture of Asians in general and Vietnamese people in particular is very fond of wood-made items, but with the current natural environment, the exploitation of wood is very bad, so we need limit. Besides, the price of natural wood is not cheap, some criteria of wood durability such as moisture resistance and termite resistance are not as high as Laminate.

Use Laminate panels to make kitchen cabinets, feng shui shelves, beds, counters, wall tiles, ceiling tiles, wardrobe, TV shelves, decorative walls. For some furniture items and other applications in construction, people prefer to use leather, stone and metal laminate panels. When pressed Laminate surface on these items will bring a very luxurious and modern feeling, making your living space more classy.

Application of laminate panels in interior of apartments, apartments and neoclassical architectural styles, for example, white walls do not need to be painted on wood but only pressed white Laminate AICA panels on.

| Anti-Virus | Anti-Bacteria |

|---|---|

| The SIAA brand mark is borne on products that are under quality control and information disclosure by the guidelines of the Society of Industrial Technology for Antimicrobial Articles based on the basis of the results evaluated by ISO 21702 method. ・ Antiviral treatment does not cure or prevent disease. ・ In compliance with SIAA safety criteria |

The SIAA brand mark is borne on products that are under quality control and information disclosure by the guidelines of the Society of Industrial Technology for Antimicrobial Articles based on the results evaluated by ISO22196 method. |

| Anti-viral product list | |||||

| Classification | Product name | Type of progressing agent | Processing method | Processed part | Registration number |

| HPL | AICA Virutect | Synthetic organic compounds | Integrated | Surface layer | VN0612765X0001T |

| Manufactured by Aica Laminates Vietnam Co., Ltd. | |||||

| Anti-bacterial product list | |||||

| Classification | Product name | Type of progressing agent | Processing method | Processed part | Registration number |

| HPL | Aica HPL | Inorganic | Integrated | Surface layer | VN0122765X0002Q |

| HPL | AICA CELSUS | Inorganic | Integrated | Surface layer | VN0122765X0003R |

| HPL | AICA Virutect | Inorganic | Integrated | Surface layer | VN0122765X0001P |

| Manufactured by Aica Laminates Vietnam Co., Ltd. | |||||

AICA HPL is currently the distributor of AICA Japan Laminate panels in Vietnam.

There are many places where Laminate panels can be distributed, including construction or not. Laminate panels in Vietnam market today are mostly originated from India and China, a few high-end brands from Europe and Japan, including AICA brand is the No. 1 Laminate brand in Japan. Currently, with diverse product designs, many outstanding advantages and unique product lines such as anti-fingerprint product line, copper core line, leather grain, wood grain, stone pattern, metal ... All Laminate designs of AICA are characterized by being very authentic, more than 90% genuine.

In Vietnam, AICA HPL currently distributes Laminate panels of AICA Laminate. AICA Japan has built the first and only factory in Vietnam currently producing laminate panels operated by Vietnamese under the direction and technology of Japanese people, quickly responding to bulk orders in Vietnam. in particular and Southeast Asia in general. Besides, AICA HPL also has Laminate product lines with more reasonable prices from AICA brand Async, Splendor brand from India, Neo - Gecko from China ... Laminate lines at AICA HPL are very diverse models, colors, large inventory and prices are suitable for many different needs segments.

Certificate of business registration number 0108993025

Copyright © 2024 AICA HPL